Producer Profiles

SACMI Group: Italy`s Packaging and Bottling Solution Provider

The Group consists of more than 80 companies, has production plants and support companies in 26 countries and employs about 3500 people.

SACMI is a multinational group of companies which manufactures machines and complete plants for the Ceramics, Packaging (Beverage and Closures & Containers), and Food and Automation industries - markets in which it is a recognized worldwide leader. The Sacmi Group has over 80 companies in 28 countries, production plants, distribution firms and service, once controlled by the parent company in Imola, Italy. The Sacmi Group provides efficient assistance and services all over the world thanks

Service Provided by The Sacmi Group

- Ceramics

Complete plants for

- 3rd firing and trims

- Tiles

- Flat Extruded

- Sanitaryware

- Tableware

- Refractories / Complex ceramic products

Solutions for

- Carbon

- Technical Ceramics

- Cold Forging

- Sheet Metal

- Powder Meta

- AUTOMATION

- Vision systems for Quality Control

- Vision Systems for the Environment

- Olfactory systems

- NIR Systems

- MES and Plant Operation Systems

- SERVICE COMPANIES

- Administrative services

- Shipping and Logistics

- Technological services for the manufacturing industry

- IT services

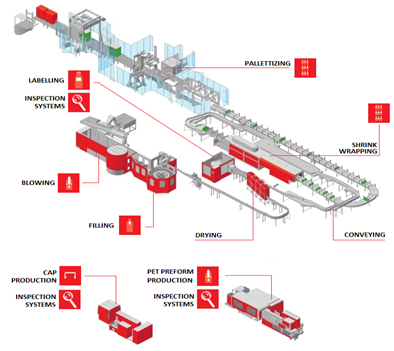

SACHMI offers a wide range of services specifically for beverage industry, out of which their primary service is Packaging and Bottling. In Beverage industry, SACMI group is leading player and play a key role in setting up a plant and production automation Products.

Packaging & Bottling Services

1.Complete Bottling Plant and Beverage Equipment

2.Closures

|

Plastic Cap Manufacturing Compression lines. |

Plastic Cap Manufacturing injection lines. |

|

Crown Cap manufacturing lines |

Aluminium Cap manufacturing lines |

|

Colora Cap Digital Printing System for caps |

Automatic Buffer

|

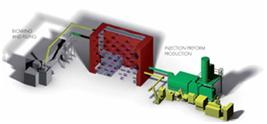

3.PET Preforms

A preform is an intermediate product that is subsequently blown into a polyethylene terephthalate (PET) container. Preforms vary in neck finish, weight, colour and shape, and are specifically designed to meet the needs of customers in different market segments.

|

PET Preform Injection systems |

Automatic Buffer |

Inspection Systems for PET performs |

4.Automatic buffer for caps and performs

Sacmi Caps and Preform Buffer is the automatic storage system for caps and preforms that creates the final connection between caps & preform production and blowing/filling. The result is the first real production line for the beverage from pellet to pallet.

|

|

5. Blowing Machines

The Blowing Machine has excellent compactness and user-friendliness make this an extremely interesting, advantageous solution for those looking to minimise the number of workers on the bottling line and reduce the risks of bottle contamination.

6.Filling Solutions

With its wide range of technologies for the filling and packaging of plastic containers, glass bottles, and cans, Sacmi Filling presents a vast offer of products to the world of drinks and liquid foods.

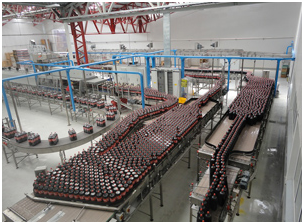

7.Conveying Systems and Automation

Bottle and Pack Conveyors is fully “Made in Italy”, Sacmi conveying systems are characterized by modular design and high-quality components. They are equipped with the stainless steel frame and parts, and with chains of leading brands in the most technologically advanced models. Bottle conveyors provide the connection among the various machines in the line and their size is designed to guarantee maximum line efficiency, optimum use of the available space, reduction in personnel required, and decreased a level of operating noise. Pack conveyors are developed to transport all different types of packages (crates, boxes, packs, multipacks, etc.). The product range is complete and covers all the needs of the beverage industry, including magnetic curves, active transfer, accumulation tables, pressure-less inliners, special applications and units.

|

|

8.Labelling

Complete range of automatic labelling machines (labellers) for glass, plastic and metal containers, for the beverage, food, household /personal care, wines/spirits, chemical, pharmaceutical, and packaging industries.

9.End of the line Automation

The machine is suitable to handle a different kind of products, with a guarantee of a high degree of reliability and advanced technology. Automatic machine made of a supporting frame structure, complete with supporting arm for the headpieces that, through a motor, moves up- and downwards for taking and depositing the bottles into the cartons. All movements are carried with high precision sliding components. The translation system motion is carried out by means of Brushless motor-reducers, checked by their own electronic drives.

10. Form-Fill-Seal

The Form-Fill-Seal technology – starting from two reels of material, one of thermoformable plastic film for the container, and one of lid film sealable on the plastic web, - allows producing finished packages that are formed, filled with product and sealed in a unique process. Different cutting configurations are applicable according to marketing requirements. Compared to the fill and seal technology such process entails responsibility for the complete production cycle and makes it possible to reduce packaging storage costs and at the same time ensure more reliable hygienic conditions.

11. MES and Plant Operation Systems

H.E.R.E. (Human Expertise for Reactive Engineering) is a new set of software solutions designed to network production processes by supervising information and exchanging it with the machines to which they are connected.

The advantages of H.E.R.E. positively affect production processes and Smart Factory growth strategies. An overall view of the plant allows for better monitoring of processes and enhances machine diagnostics.

Reports aid optimisation of resources and process planning.

Data exchange with the ERP speeds up processes.

- Overall view of the plant: every single stage of production plant operation is monitored, thus allowing improved process management.

- Monitoring and diagnostics: diagnostic power has been given a boost.

- Reports: H.E.R.E. generates production reports directly on the basis of data received from machines and departments.

- Production management: data supplied by H.E.R.E. optimises manufacturing management.

- Data exchange with ERP: H.E.R.E. exchanges information directly and automatically with the ERP.

- Data available anywhere in the world: H.E.R.E can send reports to mobile devices, making them available anywhere in the world.

About Cannabis Drinks Expo

Cannabis Drinks Expo is a must-attend event for those curiously eying the future of the burgeoning U.S. cannabis industry.

Cannabis Drinks Expo is a must-attend event for those curiously eying the future of the burgeoning U.S. cannabis industry.

We also cover the key issues surrounding the likelihood and timescale for legalization to other countries, as well as the impact of legalized cannabis on the traditional alcoholic and non-alcoholic drinks markets globally.

Who should Visit?

Cannabis Drinks Expo promises to be relevant for anyone involved in the development, production, distribution and retailing of cannabis and related products. It will also provide a vital networking opportunity for political analysts, medical experts and those involved in the development and implementation of legalized cannabis into new markets.

Attend Cannabis Drinks Expo in preferred city

Who should exhibit?

If you’re serious about the cannabis drinks category, we’re still keeping it as real as ever. At Cannabis Drinks Expo, our goal is to empower you with knowledge, network, and platform so you can grow and build your cannabis drinks business. CDE is where you will find cannabis brands and suppliers who are serious about building their business in this category exhibit.

Exhibit in preferred city

Potential exhibitors include (but not limited to): Medical marijuana producers, Cannabis growers, Cannabis producers/ product developers, Cannabis processors, Cannabis distributors/transporters, Wineries, Breweries, Distilleries, Branded drinks companies, Drinks manufacturers/producers, Pharma companies, Equipments and service providers, CBD manufacturers, Marijuana-Infused products and edibles providers, Testing and laboratory services, Logistics and supply chain operators, Drinks distributors/wholesalers, Drinks importers, Lobbyists/ public affairs businesses, Political advisors, and more.